Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

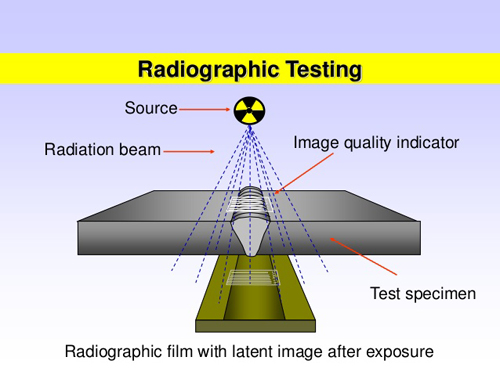

Radiography-TestingUsing radiography, the part is exposed to the source while a film is positioned behind the part to be inspected. The film is then developed and is reminiscent of a film negative.

Based on the actual indications on the film and density differences a determination can be made regarding the size and orientation of imperfections within the material as well as the their location relative to the weld. We are then in a position to determine whether or not the defect passes or fails based on the accept/reject criteria within the codes.

We can´t spell SUCCESS without You

Your trust and support drive our commitment to excellence. At SV TECH, we strive to deliver top-quality services tailored to your needs. Join hands with us and experience reliable, professional, and innovative solutions.

C-5076, Bhumi Commercial Complex, Kalamboli Street Market, Kalamboli, New Mumbai - 410218

Industrial Complex, MIDC Shiroli, Kolhapur-416122

K-181,Pocket-k,Sarita Vihar, New Delhi-110076.

A Satyanarayan. P.No. A/148,New Ramnagar, Chilka Nagar Hyderabad.

14 Bhaktinagar society,Near VImal Washing Factory, Vastral Road, Amraiwadi Ahmedabad.

About

WhatsApp us