Various types of hardness like:

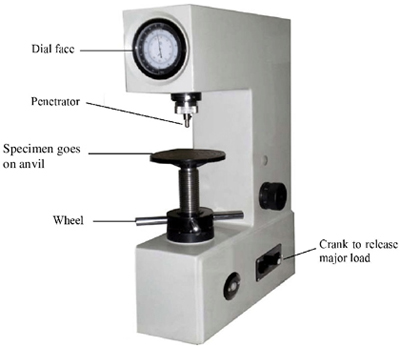

Equipments We Use:

The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe a material’s ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). The hardness number can be converted into units of Pascal’s, but should not be confused with pressure, which uses the same units. The hardness number is determined by the load over the surface area of the indentation and not the area normal to the force, and is therefore not pressure.

Brinell is best known today for the Brinell hardness test, which he proposed in 1900. In this test a 10-millimetre diameter hardened steel or carbide ball is pushed into the surface of the material being tested, with a 3000 kg imposed load. The depth to which the ball penetrates the material surface is an indication of the Brinell hardness number, which is calculated as follows:

BHN = load in kilograms divided by the spherical area of the indentation in square millimetres (refer to scale for method of calculation) It is a rapid, non-destructive (except at the surface being tested) means of determining the hardness of metals. This area is a function of the ball diameter and the depth of the indentation. With minor variations, his test still remains in wide use. This method is best for achieving the macro-hardness of material, particularly those materials with heterogeneous structure.

A more precise term is “micro indentation hardness testing.” In micro indentation hardness testing, a diamond indenter of specific geometry is impressed into the surface of the test specimen using a known applied force (commonly called a “load” or “test load”) of 1 to 1000 gf. Micro indentation tests typically have forces of 2 N (roughly 200 gf) and produce indentations of about 50 μm. Due to their specificity, micro hardness testing can be used to observe changes in hardness on the microscopic scale. Unfortunately, it is difficult to standardize micro hardness measurements; it has been found that the micro hardness of almost any material is higher than its macro hardness. Additionally, micro hardness values vary with load and work-hardening effects of materials.

We can´t spell SUCCESS without You

Your trust and support drive our commitment to excellence. At SV TECH, we strive to deliver top-quality services tailored to your needs. Join hands with us and experience reliable, professional, and innovative solutions.

C-5076, Bhumi Commercial Complex, Kalamboli Street Market, Kalamboli, New Mumbai - 410218

Industrial Complex, MIDC Shiroli, Kolhapur-416122

K-181,Pocket-k,Sarita Vihar, New Delhi-110076.

A Satyanarayan. P.No. A/148,New Ramnagar, Chilka Nagar Hyderabad.

14 Bhaktinagar society,Near VImal Washing Factory, Vastral Road, Amraiwadi Ahmedabad.

About

WhatsApp us